Mill Lining Systems ... specialized rubber compounds and liner design with the goal of enhancing mill ... complement the lifter bar operation for ball ...

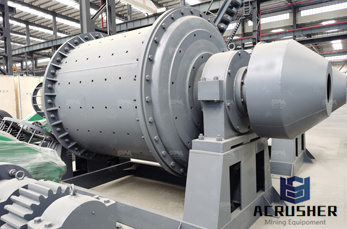

Ashoka is one the leading Ball Mills Manufacturers In India, the ball mill is a horizontal cylindrical shaped equipment used for grinding hard minerals to power fines.

They are ball mill rubber liners, abrasive rubber screens, polyurethane screens, rollers, grinding balls, flotation machine rubber stator and rotor, and belt conveyer.

Ball Mill/Ball Mill Design/Balls MillsShanghai Minggong Ball Mill... ... The rubber lining plate is short for rubber lining plate used on the ball mill...

Ball Mill linings from Multotec provide long life, throughput and high grinding efficiency.

Case Studies : Ball Mill Relining . Ball milling is a primary method of grinding coarse materials to a fine powder. Typically employed in the ceramics, metallurgical ...

PATTERSON''s unmatched Ball and Pebble Mill custom design experience and manufacturing capability ... PATTERSON Batchtype Ball Pebble Mills. ... Lining inside Ball ...

Modifying the ball mill performance parameters for ball mill operations normally calls for considerable investment. Buf many mines are now obliged to increase ...

Good Quality Ball Mill Liners, Mill Liners Supplier From China Wuxi Orient Antiwear Engineering Co.,Ltd..

Versatile system based on standard modules 2 The FLSmidth ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement.

The Ball Mill Lining DesignOriginal optimization. Modifying the performance parameters for ball mill operations normally calls for considerable investment.

Kedar rubber is one of the leading Manufacturer and exporter of Rubber liner and mill rubber liners in Ahmedabad, Gujarat and India.

Ball Mill Lining Design, Wholesale Various High Quality Ball Mill Lining Design Products from Global Ball Mill Lining Design Suppliers and Ball Mill Lining Design ...

Selection and design of mill liners. ... a very large scale three dimensional DEM to explore media behaviour and ball size segregation in a two chamber cement ball mill.

ball mill liner design in first chamber crusher ... Ball Mill Liners Design Concept. Lining of grinding ball mill is made from the synthetics raw rubber and natural ...

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index ...

Trelleborg Rubber Mill Liners Trelleborg introduced wear resistant rubber to Ball Mills in the 1920''s, with the first installation experiment carried

ball mill alumina lining brick. Toggle ... refractory ball mill in ... to provide "Turnkey Solution for Mineral Processing Plant" including design and ...

Wuxi Orient Antiwear Engineering Co.,Ltd. is best Ball Mill Liners, Mill Liners and Cement Mill Liners supplier, we has good quality products service from China.

How to Optimize Ball Mill Lining Design. Modifying the performance parameters for ball grinding mill operations normally calls for considerable investment.

Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put a unique spin on steel and lined mills.

Ball Mills PolyMet ball mill liners are typically less ... The design is based on ... Highperformance tailor made mill lining systems designed to ...

new design ball mill aluminum grinding,US 20,000 72,000 / Set, New, Ball Mill, AC from Zhengzhou Jiangtai Heavy Industrial Machinery Co., Ltd. on ...

Metallic mill linings. The large mills of today process high tonnages, and every minute of production counts. Proper material selection, optimized lining design and ...

WhatsApp)

WhatsApp)